Hydraulic hoses are an integral part of numerous industries, helping power heavy machinery, facilitate fluid transmission, and support essential operations. Without them, industries like construction, agriculture, and manufacturing would come to a halt. This article provides a comprehensive guide on hydraulic hoses, their types, applications, maintenance, and much more.

What is a Hydraulic Hose?

A hydraulic hose is a specialized tube designed to convey hydraulic fluid between different components of a hydraulic system. These hoses are flexible and reinforced to handle high pressures while delivering fluid efficiently.

Basic Components of a Hydraulic Hose

Hydraulic hoses are composed of three key layers: the inner tube (for fluid transport), the reinforcement layer (to handle pressure), and the outer cover (for protection from external elements).

Types of Hydraulic Hoses

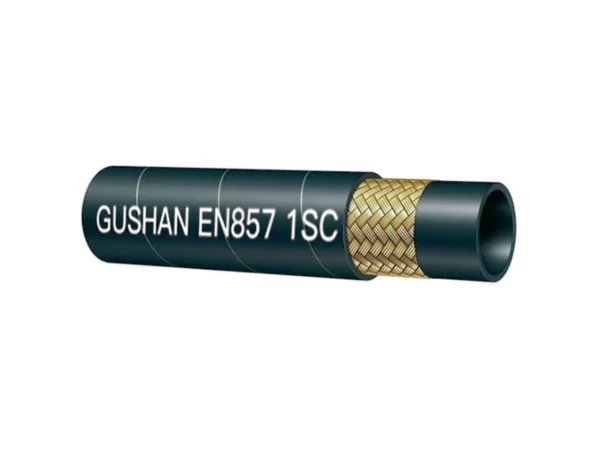

Braided Hydraulic Hoses

These hoses are reinforced with one or more layers of braided wire, offering flexibility and moderate pressure resistance.

Spiral Hydraulic Hoses

Spiral hoses feature multiple layers of spiral-wound wire, designed to handle higher pressures and more demanding applications.

Thermoplastic Hydraulic Hoses

Made from a combination of thermoplastic materials, these hoses are lightweight and resistant to abrasion.

Materials Used in Hydraulic Hoses

Rubber Hoses

Rubber is the most commonly used material in hydraulic hoses due to its flexibility and durability.

Thermoplastic Hoses

Thermoplastic hoses are more lightweight and are often used in environments where weight and chemical resistance are important.

Stainless Steel Hoses

For high-temperature applications, stainless steel hydraulic hoses are preferred due to their heat resistance and durability.

Hydraulic Hose Construction

Tube

The innermost layer of the hydraulic hose that directly transports the hydraulic fluid.

Reinforcement Layers

This layer is made up of either braided or spiral wires to reinforce the hose, helping it withstand high pressures.

Cover

The outermost layer protects the hose from abrasion, corrosion, and external environmental factors.

How Hydraulic Hoses Work

Hydraulic hoses play a vital role in transmitting pressurized fluids in hydraulic systems. These systems are used to power machinery, facilitate motion, or perform tasks that require high force. To understand how hydraulic hoses work, it’s important to break down the process into several key functions:

Fluid Transmission

Hydraulic hoses are designed to transport hydraulic fluid (such as oil or water-based fluids) between different components in a hydraulic system. These hoses serve as flexible tubes that connect critical parts like pumps, valves, actuators, and cylinders. The fluid inside the hose moves under pressure, allowing machinery to perform various tasks like lifting, pushing, or moving heavy loads.

The hose’s flexibility is crucial because hydraulic systems often operate in environments with complex movements or tight spaces. The ability to bend and flex without kinking ensures that fluid flow remains uninterrupted, even under challenging conditions.

Pressure Management

Hydraulic hoses are designed to withstand high-pressure levels, which is one of their most important functions. The hydraulic fluid inside the hose is pressurized by a pump, and this pressure is what powers the machinery. Hoses must be able to maintain this pressure without bursting or leaking. They achieve this by using reinforced layers within the hose structure.

Controlling Flow Rate and Speed

The hydraulic fluid moving through the hose needs to be controlled for specific functions. The flow rate and speed of the fluid directly affect how fast or slow the machinery operates. Hoses of different diameters are used depending on the required flow rate; larger hoses allow more fluid to move through them, while smaller hoses restrict the flow for more precise control.

For instance, in an excavator, the hydraulic hose controls the fluid flow to the hydraulic arms, ensuring the machine can perform both heavy-duty lifting and precise movements.

Temperature Management

Hydraulic hoses also play a role in managing the temperature of the hydraulic fluid. During operation, hydraulic systems generate heat, which can affect the performance of the fluid and the components. Hydraulic hoses are often made from materials that can withstand high temperatures without degrading. Additionally, certain hoses are designed with temperature-resistant outer layers, helping to prevent overheating or freezing of the fluid.

Maintaining Fluid Integrity

Hydraulic systems rely on clean, uncontaminated fluid to function effectively. Hydraulic hoses are designed to prevent external contaminants (such as dust, dirt, or moisture) from entering the fluid stream. The outer cover of the hose acts as a protective barrier, ensuring the fluid remains clean while traveling through the system.

FAQs

What is a hydraulic hose used for?

Fluid Transfer: Primarily, hydraulic hoses are used to transport hydraulic fluid (oil or water-based fluids) under pressure from one component to another in a hydraulic system.

Power Transmission: Hydraulic hoses facilitate the transfer of energy within hydraulic systems, allowing for the operation of hydraulic motors, cylinders, and other equipment.

Flexibility and Mobility: The flexible nature of hydraulic hoses enables movement and connection between stationary and moving components, making them ideal for applications where equipment may pivot or shift.

Pressure Resistance: Hydraulic hoses are designed to withstand high pressures, often exceeding several thousand psi, making them suitable for demanding industrial applications.

What factors should I consider when choosing a hydraulic hose?

Pressure Rating: Ensure the hose can handle the system’s maximum pressure.

Temperature Range: The hose material must withstand the temperatures of the hydraulic fluid.

Fluid Compatibility: Ensure the hose material is compatible with the hydraulic fluid being used.

Hose Length and Diameter: Measure the required length and diameter for proper fit and flow.

Bend Radius: Take note of the minimum bend radius to avoid kinking or rupturing the hose.

How long do hydraulic hoses last?

The lifespan of a hydraulic hose can vary based on several factors, including the quality of the hose, operating conditions, and maintenance practices. On average, hydraulic hoses can last anywhere from 5 to 10 years. Regular inspections and proper use can increase their lifespan.

Conclusion

Understanding hydraulic hoses, their applications, and maintenance is essential for ensuring the safety and efficiency of hydraulic systems. Regular checks and proper installation can help prevent failures and prolong the life of your hydraulic hoses. If you have more specific questions or scenarios in mind, feel free to ask!